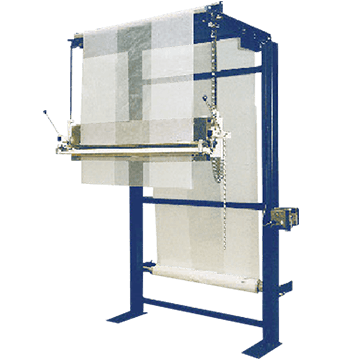

Krimphoes / rekhoes verpakkingsmachines

Wanneer gebruik je een krimphoes of rekhoesverpakkingsmachine?

Verpakken met krimphoezen en rekhoezen zijn twee veelgebruikte verpakkingsmethoden die in verschillende industriën worden gebruikt om goederen en producten te beschermen en te beveiligen. Zowel krimphoezen als rekhoezen bieden een effectieve en efficiënte manier om items te beschermen tegen schade, stof en/of vocht tijdens transport en opslag.

Wat is het verschil?

Krimphoezen zijn "zakken" van krimpfolie die om een product of pallet worden gelegd en door warmte worden gekrompen. Het krimpproces wordt meestal gedaan met behulp van een heteluchtpistool of een krimptunnel. Door de hitte krimpt de krimpfolie en zet deze strak om het product of de pallet, waardoor een sterke en beschermende folie ontstaat. Ze bieden een uitstekende bescherming tegen stof, vocht en andere invloeden van buitenaf. Omdat de krimpfolie transparant kan zijn blijft de inhoud zichtbaar wat handig is bij het identificeren en sorteren van goederen.

Rekhoezen daarentegen worden gemaakt van een elastische rekfolie en wordt over een product of pallet getrokken. De rekfolie wordt vervolgens rond het product gespannen en hecht zich aan de lading waardoor een stevige en veilige bescherming ontstaat. In tegenstelling tot krimpfolie is rekfolie niet transparant, wat de inhoud kan beschermen tegen nieuwsgierige blikken. Rekhoezen bieden een goede bescherming tegen stof en vocht, maar bieden mogelijk niet dezelfde bescherming tegen stoten of beschadigingen als krimpkappen.

Welke voordelen biedt een krimphoes- of rekhoesverpakkingsmachines en waar worden ze gebruikt?

Beide verpakkingsmethoden hebben hun voordelen en toepassingsgebieden.

Voordelen:

- Schade verminderen

- Productintegriteit waarborgen

- Klanttevredenheid verhogen

Rekhoezen zijn bijzonder geschikt voor het vervoeren van producten die een strakke pasvorm en een hoge mate van bescherming tegen beschadiging vereisen. Krimphoezen daarentegen zijn flexibeler en zeer geschikt om pallets met verschillend of onregelmatig gevormde producten te beschermen. Ze kunnen gemakkelijk over verschillende maten en vormen worden getrokken en bieden een veilige en stevige verpakking.

Over het algemeen bieden beide verpakkingsmachines effectieve en praktische verpakkingsoplossingen die helpen bij het beveiligen en beschermen van goederen tijdens transport en opslag. De beslissing om een krimp- of rekhoesverpakkingsmachine te gebruiken hangt af van de specifieke behoefte van het product en de verpakkingseisen.

Wij adviseren u graag!

Wij adviseren u graag bij het vinden van de juiste krimp- of rekhoesverpakkingsmachine. Ons advies is speciaal afgestemd op uw wensen en behoeften! U kunt contact met ons opnemen via 030 248 48 48 online via ons contactformulier of via de chat.

Onze focus ligt op uw product

Königsberger Straße 5

42277 Wuppertal

Duitsland

0202 94 7090 85

info@contimeta.com

Bronsyxegatan 9

21375 Malmö

Zweden

040 22 89 80

info@contimeta.com

Savannahweg 15

3542 AW Utrecht

Nederland

030 248 48 48

info@contimeta.com

Boeierstraat 51

9000 Gent

België

09 253 05 09

info@contimeta.com

Nederland

Nederland