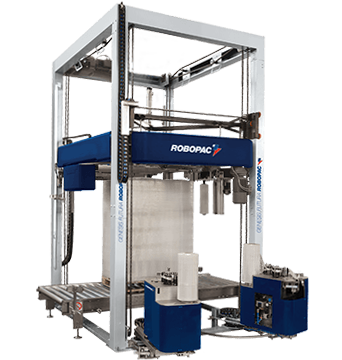

Palletwikkelaars

Wij hebben voor elk volume een geschikt model. Aantrekkelijke leasecontracten!

Meer informatieLees minderArmwikkelaars halfautomatisch

Armwikkelaars automatisch

Welke mogelijkheden biedt een palletwikkelaar voor het zekeren van palletladingen?

Een palletwikkelaar wordt gebruikt om pallets in beschermfolie (wikkelfolie of stretchfolie) te wikkelen om ze te beschermen en de goederen bij elkaar te houden tijdens transport of opslag. Ze zijn vooral handig in industrële en logistieke bedrijven, waar pallets vaak over lange afstanden worden vervoerd en worden blootgesteld aan verschillende weersomstandigheden. De machine wikkelt een dunne laag wikkelfolie om de pallet om deze vast te zetten en te stabiliseren. De trend is, om folie te besparen en daarvoor wikkelfolie steeds dunner te maken met behoud van de gewenste eigenschappen. Contimeta is daarin geslaagd met o.a. nanofolie. Minder folieafval maar wel een gegarandeerd een goed verpakte pallet.

Er zijn een paar dingen waarmee u rekening moet houden bij het kiezen van een palletwikkelaar die het beste bij u past.

Waar moet je op letten bij het kiezen van de beste passende wikkelaar?

Palletwikkelaars kunnen handmatig of automatisch zijn en hebben, afhankelijk van het type, een controlesysteem om het proces te automatiseren en arbeid te minimaliseren. Het productassortiment is groot. Voor elk toepassingsgebied is er een optimale wikkelmachine. Wij adviseren u niet alleen te letten op het gewicht en de vorm van de palletlading, maar ook op de gewenste prestaties, snelheid, spanning en folieverbruik.

Waarom is een Contimeta palletwikkelaar een goede keuze is.

Er zijn verschillende redenen waarom u een palletwikkelaar van Contimeta de beste keus is:

- Hoogwaardige producten: Contimeta biedt een breed assortiment wikkelaars van bekende fabrikanten die bekend staan om hun kwaliteit en betrouwbaarheid. De machines zijn robuust, duurzaam en eenvoudig in gebruik.

- Advies en ondersteuning: Contimeta beschikt over een ervaren en bekwaam team van specialisten die u kunnen helpen bij het kiezen van de juiste palletwikkelaar voor uw specifieke wensen en behoeften. Ook ondersteuning bij het onderhoud en de reparatie van de machines behoort tot de perfecte service.

- Oplossingen op maat: Contimeta biedt oplossingen op maat om ervoor te zorgen dat de palletwikkelaar perfect is afgestemd op uw behoeften en toepassingen. Het bedrijf kan ook accessoires en speciale opties aanbieden om de wikkelaar nog efficiënter te maken.

- Duurzaamheid: Contimeta biedt ook duurzame oplossingen, zoals nanofolie die gebruikt kan worden in combinatie met de palletwikkelaars.

Wij adviseren u graag!

Wij adviseren u graag bij het vinden van de juiste palletwikkelaar. Ons advies is speciaal afgestemd op uw wensen en behoeften!

U kunt contact met ons opnemen via 030 248 48 48 of via ons contactformulier of via de chat.

Onze focus ligt op uw product

Königsberger Straße 5

42277 Wuppertal

Duitsland

0202 94 7090 85

info@contimeta.com

Bronsyxegatan 9

21375 Malmö

Zweden

040 22 89 80

info@contimeta.com

Savannahweg 15

3542 AW Utrecht

Nederland

030 248 48 48

info@contimeta.com

Boeierstraat 51

9000 Gent

België

09 253 05 09

info@contimeta.com

Nederland

Nederland