Omsnoeringsband

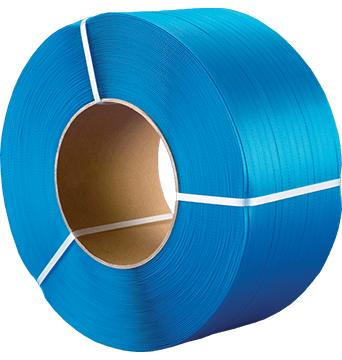

Omsnoeringsband PP

Omsnoeringsband PET

Omsnoeringsband Papier

Textielband

Composietband

Staalband

Voor het omsnoeren en bundelen met omsnoeringsband heeft Contimeta een ruim assortiment

De keuze van het juiste omsnoeringsband hangt sterk af van de toepassing en gebruikte omsnoeringsapparatuur. Aangezien de keuze van het juiste band sterk afhangt van de toepassing en gebruikte apparatuur adviseert Contimeta u graag specifiek. Contimeta levert omsnoeringsband voor handmatige en machinale verwerking, PP en PET.

Meer weten over de achtergronden van kunststofband? Klik hier.

Afhankelijk van de verwerking zijn er meerdere zaken waar u op moet letten of waar u in ieder geval rekening mee moet houden. Denk aan tolerantie-eisen, de kernmaat, dikte en breedte van het band, de rek, breeksterkte, herstellend vermogen en weerstand.

De breeksterkte, elasticiteit en spanningsverlies van omsnoeringsband

De belangrijkste karakteristiek is de minimale breeksterkte. dit wordt voornamelijk bepaald door de breedte, dikte en materiaalsoort waarvan het omsnoeringsband is gemaakt. Deze wordt in de grafiek aangeduid in daN (decaNewton). Ook de elasticiteit van het omsnoeringsband is belangrijk. omsnoeringsband zal na uitrekking willen herstellen tot zijn oorspronkelijke formaat. Na een lange periode heeft omsnoeringsband de eigenschap om te ontspannen (iets te rekken) en zijn elastische eigenschappen enigszins te verliezen. Dit noemen we spanningsverlies.

Onze focus ligt op uw product

Königsberger Straße 5

42277 Wuppertal

Duitsland

0202 94 7090 85

info@contimeta.com

Bronsyxegatan 9

21375 Malmö

Zweden

040 22 89 80

info@contimeta.com

Savannahweg 15

3542 AW Utrecht

Nederland

030 248 48 48

info@contimeta.com

Boeierstraat 51

9000 Gent

België

09 253 05 09

info@contimeta.com

Nederland

Nederland